Studentská vědecká konference 2018

Harmonogram SVK 2018

- Uzávěrka podávání přihlášek: 22. 10. 2018

- Uzávěrka nahrávání anotací: 8. 11. 2018

- SVK přednášky všech soutěžících: 22. 11. 2018

- SVK finále (přednášky 19 vítězů): 23. 11. 2018

Sborník 2018

SVK na FCHI v akademickém roce 2018/2019 proběhla ve čtvrtek 22. 11. 2018.

- 6 ústavů, 138 soutěžícíh, 19 sekcí.

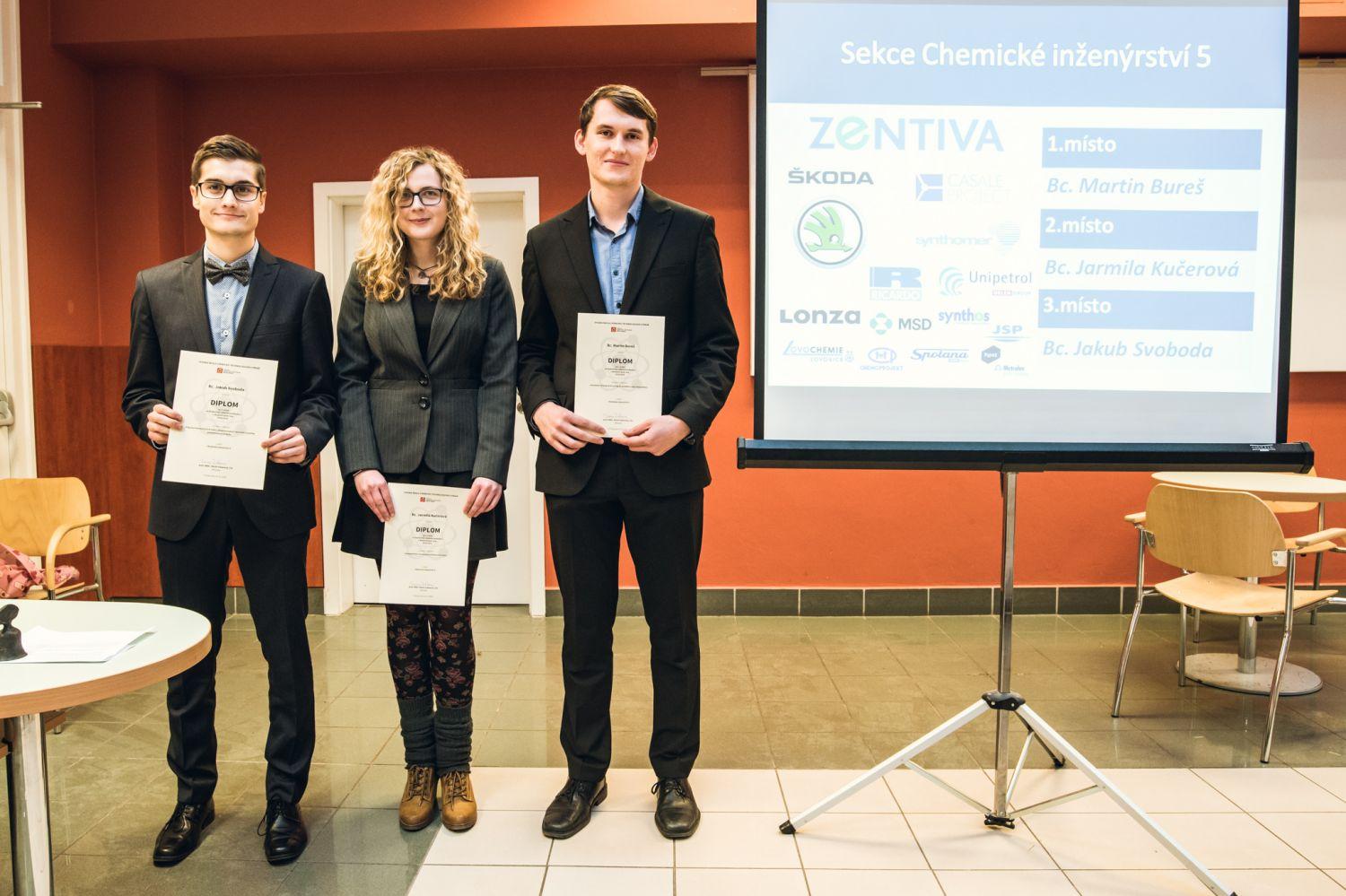

- Respirium B - 14:00 Slavnostní vyhlášení vítězů jednotlivých sekcí a předání diplomů z rukou paní děkanky prof. Marie Urbanové

V pátek 23. 11. 2018 se v posluchárně BIII uskutečnilo SVK finále, kde své práce přednesli vítězové jednotlivých sekcí.

- Délka prezentací 10 minut včetně diskuze (doporučeno 8+2).

- Složení odborné komise:

prof. RNDr. Marie Urbanová, CSc. (předsedkyně komise)

doc. RNDr. Pavel Řezanka, Ph.D. (zástupce 402)

prof. RNDr. Jiří Kolafa, CSc. (zástupce 403)

doc. Ing. Zdeněk Slouka, Ph.D. (zástupce 409)

Ing. Pavel Galář, Ph.D. (zástupce 444)

doc. Ing. Jan Mareš, Ph.D. (zástupce 445)

Ing. Pavel Calta, Ph.D. (zástupce společnosti Zentiva - hlavního sponzora SVK na FCHI) - Program:

| 8:50 | zahájení | |

|

9:00-10:00 |

9:00 |

Bc. Lenka Adamová Zvýšení výkonu balicí linky pro expedici do zámoří |

| 9:10 |

Bc. Martin Bureš Simulation of long term cycling of vanadium redox flow battery |

|

| 9:20 |

Bc. Oleksandr Volochanskyi Příprava zesilujících dendritických nano/mikrostruktur s využitím bezproudové depozice plasmonických kovů pro potřeby SERS spektroskopie |

|

| 9:30 |

Bc. Tereza Navrátilová Vývoj chemických jazyků s využitím solvatochromních derivátů stilbazolu |

|

| 9:40 |

Bc. Lenka Vatrsková Forenzní elektrochemie nových psychoaktivních látek |

|

| 9:50 |

Petr Touš Termodynamické vlastnosti a sublimace kubanu studované metodami výpočetní chemie |

|

| 10:00 - 10:20 | přestávka | |

| 10:20 - 11:20 | 10:20 |

Bc. David Palounek SERS spektroskopie červených pigmentů na povrchu plasmonických kovů: vliv excitační vlnové délky |

| 10:30 |

Bc. Martin Šourek Linking micro-scale and meso-scale models for catalytic filter |

|

| 10:40 |

Vojtěch Konderla Enhancement of graphite felt electrode for vanadium redox flow battery by in-cell graphene oxide electrodeposition |

|

| 10:50 |

Bc. et Bc. Jan Němec Analýza tlakových ztrát v automobilových filtrech pevných částic |

|

| 11:00 |

Bc. Patrik Bouřa Příprava a charakterizace biopolymerních mikrocelulárních pěn |

|

| 11:10 |

Bc. Jana Sklenářová Nanášení antistatických nanovrstev metodou elektrosprejování |

|

| 11:20 - 11:40 | přestávka | |

| 11:40 - 12:50 | 11:40 |

Bc. Ondřej Šrom Deeper insight into the dynamic light scattering technique for particle size characterization |

| 11:50 |

Bc. Jaromír Mašek Polynomial model of liquid flow |

|

| 12:00 |

Kristýna Žemlová Uživatelské rozhraní pro zpracování krystalografických dat |

|

| 12:10 |

Bc. Tereza Hanyková Ověření vlivu promocí na jednotlivé produkty společnosti Henkel s.r.o. |

|

| 12:20 |

Bc. Martin Hruška Senzor plynů na bázi křemenné krystalové mikrováhy |

|

| 12:30 |

Bc. Alexandr Zaykov Singlet Fission - Recent Advances in the Simple Theory |

|

| 12:40 - 13:00 | vyhlášení fakultních vítězů a zakončení |

Výsledky fakultního finále

1.místo

Bc. Martin Hruška

Senzor plynů na bázi křemenné krystalové mikrováhy

2.místo

Bc. Alexandr Zaykov

Singlet Fission - Recent Advances in the Simple Theory

3.místo

Bc. Martin Šourek

Linking micro-scale and meso-scale models for catalytic filter

Seznam ústavních koordinátorů SVK

402 Ústav analytické chemie - Ing. Martin Člupek, Ph.D. (Martin.Clupek@vscht.cz)

403 Ústav fyzikální chemie - doc. Ing. Ondřej Vopička, Ph.D. (Ondrej.Vopicka@vscht.cz)

409 Ústav chemického inženýrství - Dr. Ing. Pavlína Basařová (Pavlina.Basarova@vscht.cz)

837 Ústav ekonomiky a managementu - Mgr. Ing. Marek Botek, Ph.D. (Marek.Botek@vscht.cz)

444 Ústav fyziky a měřicí techniky - Ing. Vladimír Scholtz, Ph.D. (Vladimir.Scholtz@vscht.cz)

445 Ústav počítačové a řídicí techniky - Ing. Iva Nachtigalová, Ph.D. (Iva.Nachtigalova@vscht.cz)